Welcome to VANJOIN. Your satisfaction is our biggest pursuit.

Related articles:

1. What is sandwich wall panel

2. How to Install EPS Cement Sandwich Panels

3. Application of sandwich wall panels

4. Advantage of sandwich wall panels

In the last few decades, sandwich panels have proved to be a revolutionary solution in the construction industry. By definition, this material is a self-supporting component that serves two concurrent purposes – partitioning (roof or wall) and thermal insulation.

6 reasons to choose sandwich panels

The sandwich panels vary by:

* length (2 to 18 m)

* thickness (40 to 230 mm)

* core type (EPS, mineral wool, polyurethane)

* profile (smooth, micro-profile, clearline, grooved etc.)

* protective coatings (polyester SP, SP polyester Mat Pearl, Cesar PUR 55, aluzinc), with panels also used with stainless steel cladding

* cladding colours (both external and internal)

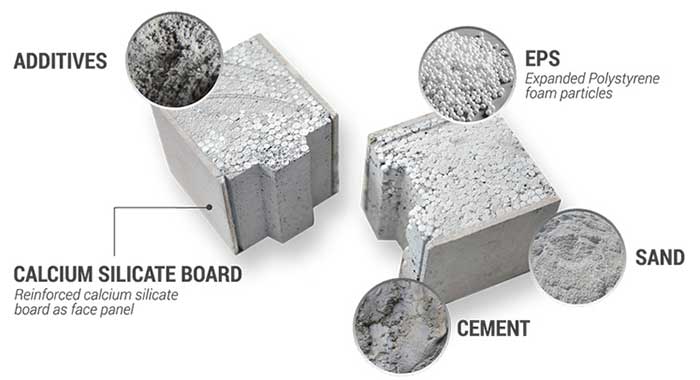

Every panel consists of several layers: core with thermal insulation, steel claddings (external and internal) and coatings protecting from mechanical damage and corrosion.

1. TIME IS MONEY

For example, let’s compare two popular technologies used in warehouse building construction.

In the first case the external partitions consist of double brick walls, while in the second case they consist of sandwich panels.

By selecting the first case we have to order the following works: wall construction, thermal insulation installation and, finally, external layer installation.

By selecting sandwich panels, the construction process is far less complicated and thus quicker and, most importantly, cheaper. Panels are finished components, suitable for easy installation, e.g. to a steel structure.

Considering the present situation on the construction services market, working time plays a key role in the cost optimisation process. The quicker the structure is completed, the less we spend on construction service costs, which have increased significantly in recent years. The rapid structure completion process also translates to earlier commencement of occupancy, which improves the return on investment for business projects.

2. THREE CORES OR SOLUTIONS DEDICATED TO SPECIFIC NEEDS

Sandwich panels are available in three basic variants. Each uses a specific panel core. Thus there are materials with cores made of polyurethane, mineral wool and EPS. Each of these solutions is intended to meet specific needs.

Polyurethane-core sandwich panels

Polyurethane is the best and most commonly used thermal insulation material on the market. After many years of market domination by older materials, such as mineral wool or EPS, today they are being replaced by better equivalents in the residential construction market, in the form of panels made of hard polyurethane foam

Sandwich panels with this core are primarily distinguished by better thermal insulation properties. The lambda of 0.022 W/mK has no equal, meaning that this type of material is selected by project owners seeking to reduce the total heating costs.

Another benefit of using this type of panel is the potential to save space inside the building. Better thermal insulation of the partitions translates to lower wall thicknesses, compared to other types of panels or masonry, while maintaining the same thermal insulation parameters.

Another equally important benefit is the lower density of the material from which the core is made (40 kg/m3). This simplifies installation significantly, because no special tools or equipment are required on the project site.

Sandwich panels with a mineral wool core

The second type of panel has two advantages – fire resistance and soundproofing efficiency. One feature of mineral wools is their behaviour in fires. Selected panels manufactured by Vanjoin are EI 240-rated, meaning that both the sealing and the fire rating of the partition is maintained for 240 minutes. This is enough time for people to leave the building safely as well as minimising the potential losses resulting from the fire.

Another important feature is to have a partition designed to prevent the transmission of excessive noise. The best panel versions feature good soundproofing capabilities, which in practice translates to a soundproofing effectiveness of up to 33 db.

Sandwich panels with an EPS core

The history of sandwich panels began with EPS (polystyrene). However, this type of core has been gradually replaced by mineral woo l and, primarily, by polyurethane.--EPS sandwich wall panel

If we compare all three types of panel, EPS lies between the mineral wool and the polyurethane in terms of thermal insulation properties; however it is inferior to mineral wool in its reaction to fire.

Sandwich panels with an EPS core are, in turn, a budget solution that can be used successfully whenever there are no stringent requirements for fire resistance or thermal insulation.

3. HOW ABOUT... CONNECTING MULTIPLE COLOURS?

Apart from the basic functions of industrial structures, attention is increasingly being paid to aesthetics. The look of our place of business, whether it be a warehouse, manufacturing plant, store or car showroom, often determines the level of trust in the brand. This is why adding unique character by the project owner to the project has become so important.

Vanjoin provides many interesting solutions, with a range of profiles and coating types (e.g. mat)

A range of selected designs can be connected freely, which can give spectacular results that attracts attention and highlights the type of business, whether the style is more classical or modern.

Due to the non-porous surface, sandwich panels are quick and easy to clean. Standard pressure washers are perfect for this purpose. The panel coating materials are completely resistant to water jet impact, thus regular cleaning will keep the structure looking new for many years.

4. ALL MATERIALS FROM ONE MANUFACTURER

Vanjoin wall panels are available with a full range of accessories. These include flashings (in any colour, including the panel colour) and all kinds of fasteners to allow panels to be fitted to any substrate (steel, reinforced concrete or wood). The project owner can also choose from a wide range of seals and gaskets to ensure the highest sealing of the partitions.

When choosing sandwich panels, the best possible access by light should also be considered. This can be provided by small windows made of polyester, which are also available with dedicated flashings. Thanks to this, the result is an appealing and well-protected structure that protects against external conditions.

5. IMAGINATION IS THE LIMIT

Sandwich panel structures can be freely arranged. The material is easy to process, so buildings can be designed with windows and gates wherever required.

6. VERSATILE APPLICATION

In travelling the length and breadth of Europe, you cannot miss the hundreds of structures made using sandwich panels. Interestingly, today these are not only industrial structures. Residential projects are becoming increasingly popular, with many design offices even creating ready concepts based on such applications.

Sandwich panels are available in wall and roof versions, which are typical for the following types of structures:warehouses and logistic hubs, production facilities, workshops, cold stores and freezers (dedicated PU-F cold storage panels), car showrooms, stores, sports and recreational facilities (swimming pools, arenas, and halls) ect.

Got a question, comment or business enquiry? We are always happy to hear from you.