Welcome to VANJOIN. Your satisfaction is our biggest pursuit.

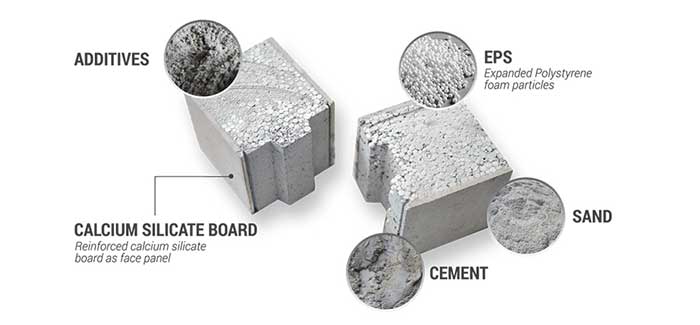

In this journey of looking for good living shelter, human being have tried and tested many building materials alternatives, from concrete blocks, AAC (Autoclaved Aerated Concrete) blocks to concrete lightweight cement wall panel, each time looking for something better. EPS, which resists moisture penetration, has a high strength-to-weight ratio and doesn’t support bacterial growth (i.e. mold). This fabricated sandwich eps wall panel is the new generation of Insulated Panels commonly referred to as precast wall panels.

This kind of building material sandwich concrete EPS lightweight wall panel also can reduce wall occupying space, increase the rate of using residential space, reduce structure load, promote building anti-seismic ability and safety performance, reduce the comprehensive cost.

The Advantages of Precast Cement EPS Wall Panels:

This kind of EPS Sandwich Wall Panel is provided with comprehensive advantage that other wall panel can’t compare with: solid, lightweight, thin body, high strength, impact resistance, strong hanging force, heat insulation, sound insulation, fire prevention, waterproof, easy cutting, can be arbitrary slot, without rendering coat, dry decoration, environmental protection. Here list the concrete lightweight EPS wall panels advantages.

1,Energy-saving, environment-friendly

Green and environment-friendly, non-harmful substance, no radiation, reusable, no construction waste, widely used in various places.

2,Fireproof

The non-inflammability of the Boyuejia board can be reached national A level standard. Under the high temperature of 1000 degrees, the fireproof feature can last four hours, do not radiate toxic gasses.

3,Increased the usable area

The thickness of the board is between 50mm-200mm. It largely saves the construction space compared with the traditional block.

4,Anti-pressure, anti-quake and anti-impact

Because of fabricated construction, 3-in-1 structure and using tongue and groove to join panels, the anti-pressure, anti-quake and anti-impact all meet the national standard.

5,Waterproof and wetproof

The water container is made of Boyuejia material without any waterproof plaster with no leakage at all. The tests show that the material has good waterproofness and dampproof. Boyuejia material can be used in the wet area such as kitchen, toilet, and basement.

6,Sound insulation

Good sound insulation, sound absorption and noise reduction functions. For example, the amount of sound insulation is up to 40dB with the 90mm thickness of the wall board, which is 2 or 3 times than the traditional wall.

7,Simple construction, high efficiency

The wall material is completely dry work, fabricated construction. The materials can be arbitrary cut according to specification. During the construction of transportation concise, pile up, no need of mortal health file, greatly reduction the time duration, and the calibration material, reducing the low construction waste. Easily transported, clearly stack and no mortar batch file largely shorten the construction period. Besides, the construction waste can be reduced by the lowly loss rate.

8,Heat preservation

Wall materials mainly are made from environmental protection and energy saving heat insulation material. With a good heat insulation and preservation function, it can keep the indoor temperature at a stable range and make the environment much more comfortable.

9,Spiking and stickability

The wall material board can be nailed directly or install expansion bolt to hang heavy loads. The single point of hanging strength is above 45kg. The surface of the board can be covered by ceramic tile, wall paper, wood panel and other materials due to the smooth and ash-free features.

10,Lightweight and economy

The core material of wall board is filled with lightweight EPS. The volume-weight is about 600-800 kg/m3. Freely plastering and the weight is only 1/6 of the traditional wall.

11, Reusable and user-friendly

The wall board can be reused in the movable interior wall such as supermarket, office, etc. The lightweight energy-saving wall board can be reusable. Dismounting and installation are simple and improved usage rate and economy saving. Also it has no construction waste and no affect other people’s normal work.

The Applications of Precast Cement EPS Wall Panels:

With excellent fireproof, best hanging force, sound insulation, heat insulation, waterproof, easy installation etc., Vanjoin light weight compound sandwich panel have been widely applyed to the special positions like partition panel of high-rise and mega-high-rise buildings.

Vanjoin light weight compound sandwich panel can automatically adjust indoor air and water content with season and climate changes, which can keep the temperature level, and such ecology effect just goes with the tide of modern residential building. It is widely applied to various modular house, low buildings, apartment, villas, and city house, etc.

Vanjoin light weight compound sandwich panel can be innovatively used as floor board. Besides the basic characteristics like sound insulation, waterproof, dampproof, this system has the outstanding advantages such as high load-bearing capacity, antistatic electricity, friction resistance, high strength, convenient for wire groove and water pipe inbuilt, corrosion resistance, no deformation, no cracking etc., which is much suitable for the fields including the floor board of additional top floor, factory, workshop, warehouse, etc.

Vanjoin light weight compound sandwich panel roof system brings brand-new added value and application idea to the traditional roof construction. This system not only solves the problem of roof leakage, but also has the advantages such as heat insulation, neat joint surface, high temperature resistance, etc. The features of light weight and high strength reduce the use of roof beam-column, reduce the construction of materials, improve security; its easy construction and installation procedures greatly shorten the construction time, which bring out its high integrated performance-price ratio.

Got a question, comment or business enquiry? We are always happy to hear from you.