Welcome to VANJOIN. Your satisfaction is our biggest pursuit.

The light weight compound sandwich panel is a kind of light weight energy saving compound board,taking fiber reinforced calcium silicon board or cement calcium silicon board as surface panel,with cement,EPS/ceramsite/perlite, sand or fly ash as fillers.to be compounded at one time, The product can replace construction materials like red brick, clay solid brick,air brick,color-coated steel sandwich board.gypsum block,wire spatial grid structure perlite board,perite porous board,etc.

lt can be widely applied to various high and low bulding such as bank,office building,hospital,school,hotel,shopping mall, amusement hall,portable dwellingas.old house reconstruction,family house and workshop,etc.

| EPS Cement Sandwich Panel | |||

| Specification L*W*T (mm) | Weight (kg/m2) | Packing (pcs/m2 per 20’GP / 40’HQ) | Application |

| 2270 / 2440 x 610 x 60 | 45-48 | 315pcs*436m2/ 384pcs*572m2 | Interior wall/ Roof system |

| 2270 / 2440 x 610 x 75 | 50-53 / 55-58 | 252pcs*349m2/ 312pcs*464m2 | Interior wall |

| 2270 / 2440 x 610 x 90 | 55-58 / 69-72 | 207pcs*287m2/ 251pcs*375m2 | Interior/ Exterior wall |

| 2270 / 2440 x 610 x 100 | 60-65 / 72-75 | 189pcs*262m2/ 240pcs*357m2 | Interior/ Exterior wall |

| 2270 / 2440 x 610 x 120 | 65-75 / 90-93 | 153pcs*212m2/ 192pcs*286m2 | Exterior wall |

| 2270 / 2440 x 610 x 150 | 80-90 / 111-114 | 126pcs*175m2/ 156pcs*232m2 | Exterior wall |

| Notes: for 2270mm panels, we use 20’GP container; for 2240mm panels, we use 40’HQ container. | |||

Applications:

Exterior Walls, Interior Partition Walls, Roof System, Floor System, Prefabricated Houses, Residential Buildings, Industrial Buildings, Commercial Buildings

Sandwich Wall Panel used for Exterior Wall

Sandwich Wall Panel used for Interior Partition Wall

Sandwich Wall Panel used for Roof System

Sandwich Wall Panel used for Floor System

Energy-saving, environment-friendly

Green and environment-friendly, non-harmful substance, no radiation, reusable, no construction waste, widely used in various places.

Lightweight and economy

The core material of EPS cement exterior wall panel is filled with lightweight EPS. The volume-weight is about 600-800 kg/m3. Freely plastering and the weight is only 1/6 of the traditional wall.

Fireproof

The non-inflammability of the Vanjoin board can be reached national A level standard. Under the high temperature of 1000 degrees, the fireproof feature can last four hours, do not radiate toxic gasses.

Waterproof and wetproof

The water container is made of Vanjoin material without any waterproof plaster with no leakage at all. The tests show that the material has good waterproofness and dampproof. Vanjoin material can be used in the wet area such as kitchen, toilet, and basement.

Anti-pressure, anti-quake and anti-impact

Because of fabricated construction, 3-in-1 structure and using tongue and groove to join panels, the anti-pressure, anti-quake and anti-impact all meet the national standard.

Sound insulation

Good sound insulation, sound absorption and noise reduction functions. For example, the amount of sound insulation is up to 40dB with the 90mm thickness of the wall board, which is 2 or 3 times than the traditional wall.

Simple construction, high efficiency

Dry work, fabricated construction. EPS cement sandwich panel can be arbitrary cut according to specification. During the construction of transportation concise, pile up, no need of mortal health file, greatly reduction the time duration, and the calibration material, reducing the low construction waste. Easily transported, clearly stack and no mortar batch file largely shorten the construction period. Besides, the construction waste can be reduced by the lowly loss rate.

Heat preservation

Wall materials mainly are made from environmental protection and energy saving heat insulation material. With a good heat insulation and preservation function, it can keep the indoor temperature at a stable range and make the environment much more comfortable.

Spiking and stickability

EPS cement sandwich panel can be nailed directly and install expansion bolt to hang heavy loads, such as TV, air conditioner, water heater. single point of hanging strength is above 45kg.

Easier for decoration

Can be decorated by ceramic tile, wall paper, wood panel and other materials due to the smooth and ash-free features.

Increased the usable area

The thickness of the board is between 50mm-200mm. It largely saves the construction space compared with the traditional block.

Reusable

Can be reused in the movable interior wall such as supermarket, office, etc. The lightweight energy-saving wall board can be reusable. Dismounting and installation are simple and improved usage rate and economy saving. Also it has no construction waste and no affect other people's normal work.

1. Alignment, transportation of materials

In the installation position of the shell wall plate, the beam is placed vertically to ensure the installation of wall panels is aligned. A 1.5 square meter board can be carried freely by 2 people.

2. Sawing of panels

According to the requirements of mobile machines with an arbitrary cut, adjust the width and length of the wall so that the risk of damage is minimized.

3. Sizing

Using a specific proportion of slurry and water to turn into a paste, use water to even up the bumps. After that, apply polymer mortar in the grooves in the wall and in the baseline of the wall.

4. Fitting the sheet

After moving the mortar-covered wall panels to their respective positions, align them vertically with the baseline. Use the crowbar to ensure the wall panels are tightly fitted with one another.

5. In place

Place the walls together closely so that excess mortar can be scraped away. Finally, temporarily fix the wall in place.

6. Adjustments

Check the adjustments of the wall and make the necessary adjustments.

7. Filling of joints

One day after the wall is set up,slurry will be used to fill in the gaps between panes.

8. Installation of crack-resistant material

Three to five days after the joints are filled, crack-resistant materials will be pasted along the joints.

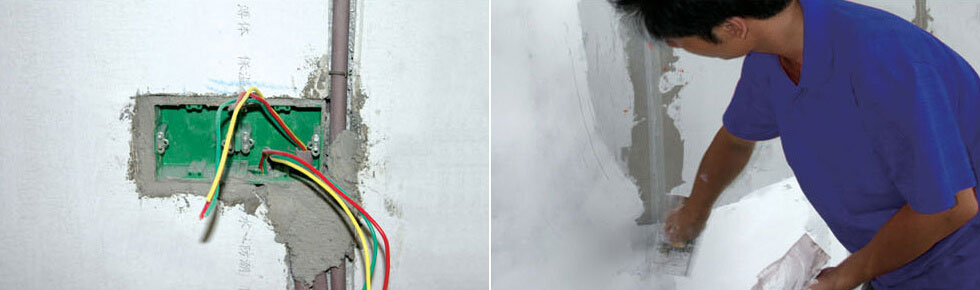

9. Insertion of wires

An electric saw will be utilized for the creation of grooves in which switch boxes and wires can be implanted. Any gaps left behind can be filled with mortar.

10. Plastering of paint

To finish the wall, tiles may be fitted without any scraping. Wallpaper may also be applied directly onto the wall.

11. Installation of door frame

Many types of door frames can be fitted in the wall. Theplywoodcan besecure with nails and wall anchor.

12. Fitting of door and window

Preparing a door and window hole on the installed wall,anchoraging it with splint or lines.

VANJOIN GROUP is a high-tech building material company specialized in the R&D, production, and sales along with great after-sale service of new energy-saving light weight eps sandwich wall panel, wall panels production line, flexible tile and flexible tiles machine.

We now own a factory with more than 20,000 m2, and with a 32,960m2 new factory under established. We have patent of maknig the sandwich wall panels, and own research group in famous universities.

Our products have been certificated by CE, BV, SGS, ISO9001 & 14000, having been widely exported to UAE, Saudi Arabia, Qatar, Iran, Iraq, Russia, Cyprus, Ireland, Egypt, South Africa, Nigeria, Kenya, Uganda, Ghana, Australia, Maldives, India, Malaysia, Thailand, Brazil, Chile, Costa Rica, etc.

Q:How long can you delivery the goods?

A:Usual order can delivery in 7-15 days upon receiving deposit payment

Urgent order can be speed production to meet client requirement

Large order can further discussing

Q:Can you offer sample for testing?

A:Of course, we can offer free small sample at your required thickness.

Q:Do you have any certificates or qualifications?

A:Yes. We have passed CE & ISO, and full set of wall panel performance testing report, including Thermal Insulation, Soundproof, Strength testing, Fireproof (performance of our sandwich panel is more than 4 hours in the heat of 1000℃.)

Q:What are the disadvantages of your sandwich panel?

A:Our panel is non-load bearing wall panel, so when build several floors or high-rise buildings, must combine with steel structure or concrete structure.

Q:When the time goes by. whether the panel might damage due to the climate change and whether it can be harmed by insects?

A:Our panel will not be damaged due to the climate change, and also will not be harmed by insects. But for more than 2 storey or high-rise building, this panel need to combine with steel structures or concrete structures. And lifespan is about 50~70 years.

Q:How would you guaranty the quality of your products and would like to know whether a warranty is available for the products we are to order?

A:The physical property of this panel will not be changed with the time goes by, generally speaking, it maybe damaged during transport or improper use or man-made damage.

Q:What is your recommendation on usage (for what kind of a construction each panel can be used in accordance with the thickness)?

A:Roof: 60mm panel

Interior Wall: 60mm 75mm, 90mm, 100mm

Exterior Wall: 100mm, 120mm,150mm etc

(Remarks: Just for your reference. Upon different client requirement, different practice.)

Q:What is the thickness of calcium silicate board independently?

A:Thickness of face board ( calcium silicon board or fiber cement board) is about 4.5mm-5mm.

Got a question, comment or business enquiry? We are always happy to hear from you.