Welcome to VANJOIN. Your satisfaction is our biggest pursuit.

Pu stone equipment is a kind of artificial stone production equipment, mainly composed of foaming machine, mold and so on.

This machine is using a polyurethane material, through high-pressure air to spray the mixture onto the surface to be covered, forming a uniform layer of foam, after a series of processing and treatment, can produce a variety of colors, textures.

The production process of PU stone equipment is simple and cost efficient. The produced products have good wear resistance,corrosion resistance, water resistance and beauty, widely used in construction, home decoration and other fields.

| Machine Size | 1500*1600*2200mm |

| Material | Polyurethane foaming |

| Foaming Principle | High pressure air type |

| Product Application | Used for the production of artificial stone/wood designs |

| Technical Parameter | |

| Operating Power | 11 KW |

| Pouring Time | 0.1-99.9s |

| Working Voltage | 380V 60HZ |

| Working Pressure | 4-7 bar |

| Control Voltage | 24V safe voltage |

| Total Machine Weight | 1.3t |

All-round manufacturing of high-pressure foaming machines, production lines, molds, and robot supporting processes.

PLC Programmable Control: The diagnostic alarm will be automatically identified in case of abnormality.

Raw Material Barrel: 304 stainless steel liner tank, which can be pressurized and vacuum defoamed, and the tank has a heating and heat preservation function.

Foaming Machine Mixing Head: High precision ball valve type, High speed dynamic spiral mixing,Easy to maintain, With automatic cleaning function.

Siemens Mortor: Variable frequency motor drive, High precision pump metering, Which can ensure accurate quantification and uniform mixing ratio.

Magnetic Coupling: High-tech permanent magnet control, No temperature rise, No leakage.

A2VK Polyurethane Metering Pump: High-precision wear-resistant gear pump, Continuous feeding, Which can guarantee ratio accuracy.

VANJOIN GROUP is a high-tech building material company specialized in the R&D, production, and sales along with great after-sale service of new energy-saving light weight eps sandwich wall panel, wall panels production line, flexible tile and flexible tiles machine.

We now own a factory with more than 20,000 m2, and with a 32,960m2 new factory under established. We have patent of maknig the sandwich wall panels, and own research group in famous universities.

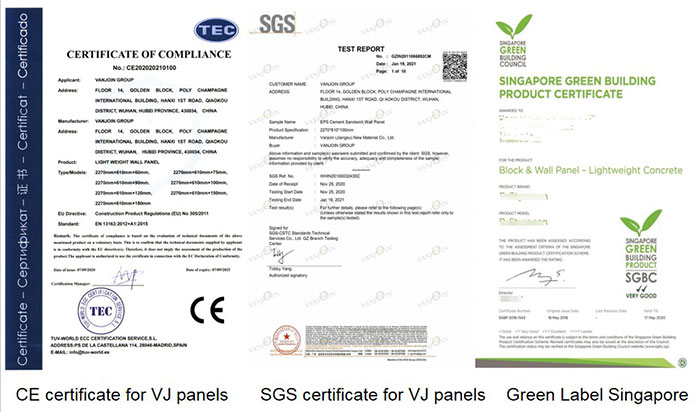

Our products have been certificated by CE, BV, SGS, ISO9001 & 14000, having been widely exported to UAE, Saudi Arabia, Qatar, Iran, Iraq, Russia, Cyprus, Ireland, Egypt, South Africa, Nigeria, Kenya, Uganda, Ghana, Australia, Maldives, India, Malaysia, Thailand, Brazil, Chile, Costa Rica, etc.

Humanized Design, Cost-effective, Safe and Explosion-proof

Advantages: Because the high-pressure foaming machine does not produce residual materials and the foam quality is good, it will save the amount of stock solution (about 5-10%).

Effect: Independent research and development of foaming equipment program, humanized design, excellent configuration, remote monitoring, fast response, good foaming effect.

Poor foaming mainly depends on whether the machine configuration and program design are reasonable.

The characteristic of our equipment is that before the problem occurs, the machine will give an early warning or automatically stop.

Choice: An equipment with reasonable control program design, sensitive auxiliary system, high precision mixing head, simple operation and maintenance will save you more cost.

Got a question, comment or business enquiry? We are always happy to hear from you.