Welcome to VANJOIN. Your satisfaction is our biggest pursuit.

Industry-specific attributes

| After-sale Service | Online technical support, Free spare parts, Other |

| Project Solution Capability | Others |

| Application | Park |

| Design Style | EUROPEAN |

| Product Type | Decking |

Other attributes

| Warranty | 5 years |

| Place of Origin | Hubei, China |

| Model Number | 146*105*2900 MM |

| Material | PE, wood powder |

| Usage | Outdoor |

| Surface Treatment | Wire Brushed |

| Product Name | PE Floor |

| Raw material | PE, Wood powder, additives, etc.. |

| Advantage | Eco-friendly / 100% Waterproof/anti-crack/ natural color |

| Accessories | kneel, clips, nail, corner cover |

| Color | teak wood, chocolate, Customized Color |

| Installation | Install Easily |

| Application Places | park, swimming pool, mountain tourism, etc.. |

Wood plastic flooring is divided into two types: co-extrusion and non co-extrusion. Co-extruded wood plastic flooring is made of specially compounded functional plastics (mainly HDPE, PP) and natural fiber (wood powder), with a certain amount of additives (anti-UV agents, anti-oxidants, coupling agents, lubricants, toners, etc.) , with special surface and core layers. The biggest difference between co-extruded wood plastic flooring and non co-extruded wood plastic flooring is the additional layer of polymer shell. This shell is fully surrounded on four sides and is extruded at high temperature at the same time as the core board. This technology is called co-extrusion technology.

Co-extruded wood plastic flooring can provide excellent stain resistance and mildew resistance due to the addition of a protective layer. General stains can be wiped or rinsed, and the color can be maintained for a long time.

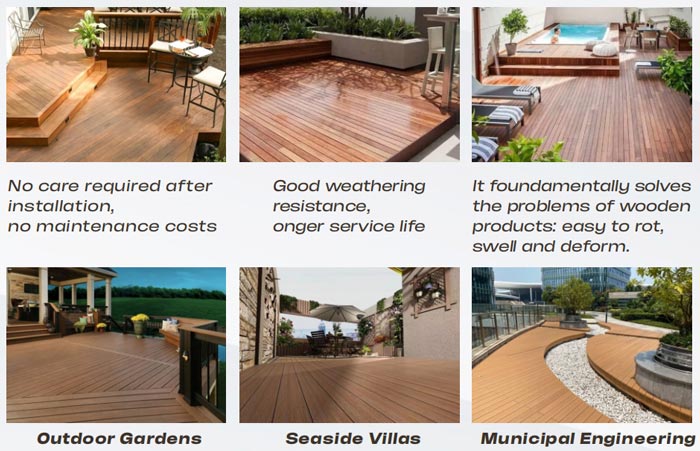

PE floor is widely used in outdoor gardens, seaside villas, municipal engineering projects, etc..

It can be used in environments where traditional wood products cannot be used.

Why Chose PE Floor?

1.No care required after installation, no maintenance costs

2.High weather resistance, longer service life

3.Waterproof, B1 flame retardant, insect-proof, sun-proof

4.It fundamentally solves the problems that wooden products are easy to rot, swelling and deformation after absorbing water and getting damp in a humid environment.

Keel Installation:

1. Use an electric drill to drill holes in the concrete ground. Insert the expansion bolt sleeve into the hole, tighten with screws, and install expansion bolt on the same side of the keel. The fixed points are spaced 80-100cm apart. The distance between the two roots is controlled to 30cm, and the roots are fixed on the ground and cannot be suspended in the air.

2.The maximum distance between the end of the board and the nearest keel is 5cm.

3.The keel is not structural component and can only be placed on the ground, not to be fixed to the ground or to the other keel. There must be a 10mm gap between the end of the keel and the wall. A 10mm gap must be left when join 2 joists.

Floor installation:

1.Fix the starting fixing clip at the starting point of the keel, and the keel should be vertically aligned. The distance between the keel and the wall is 10mm.

2.The distance between both ends of the floor and the nearest keel is maximum 50mm.

3.After the first board is fixed, place the hidden buckle on the other side of the first board, tighten the screws on the fasteners in sequence. Then use the buckle to insert the next piece of floorboard and screw it tightly. Repeat the above steps to install other floors in sequence.

4.According to the size of the floor and keel, apply the matching edge banding.

VANJOIN GROUP is a high-tech building material company specialized in the R&D, production, and sales along with great after-sale service of new energy-saving light weight eps sandwich wall panel, wall panels production line, flexible tile and flexible tiles machine.

We now own a factory with more than 20,000 m2, and with a 32,960m2 new factory under established. We have patent of maknig the sandwich wall panels, and own research group in famous universities.

Our products have been certificated by CE, BV, SGS, ISO9001 & 14000, having been widely exported to UAE, Saudi Arabia, Qatar, Iran, Iraq, Russia, Cyprus, Ireland, Egypt, South Africa, Nigeria, Kenya, Uganda, Ghana, Australia, Maldives, India, Malaysia, Thailand, Brazil, Chile, Costa Rica, etc.

Q:How long can you delivery the goods?

A:Usual order can delivery in 7-15 days upon receiving deposit payment

Urgent order can be speed production to meet client requirement

Large order can further discussing

Q:Can you offer sample for testing?

A:Of course, we can offer free small sample at your required thickness.

Q:Do you have any certificates or qualifications?

A:Yes. We have passed CE & ISO, and full set of wall panel performance testing report, including Thermal Insulation, Soundproof, Strength testing, Fireproof (performance of our sandwich panel is more than 4 hours in the heat of 1000℃.)

Q:Can our company make customized Wall Panel?

A:Yes, we can customized wall panel according to photos and size provided by clients. The material and color can be changed as clients' requests. We welcome OEM orders.

Q:What's our payment term?

A:Our payment term is by T/T 30% deposit, 70% balance must by T/T before shipment. Our price is based on FOB or CIF.

Q:Can you guarantee your products?

A:Yes,we guarantee your 100% satisfaction on all our products. We have more than 15 years' experienced workers. We are certified by ISO9001 ISO45001 ISO14001 certification, good quality guarantee.

Got a question, comment or business enquiry? We are always happy to hear from you.