Welcome to VANJOIN. Your satisfaction is our biggest pursuit.

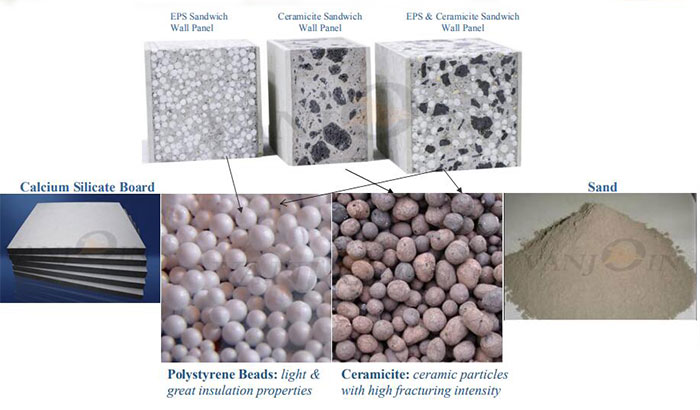

The surface boards are the materials to be used for the production of EPS wall boards. Currently, the mainstream panels in the market are calcium silicate boards and fiber cement boards. Both panels can be used as surface panels for EPS wall panels, and customers choose which panels to use based on the local market.

Why we choose calcium silicate board, not fiber cement board in China?

1. Compared with fiber cement board, calcium silicate board has rougher surfaces, which makes it connected with the in-between sandwich layer more tightly.

Calcium silicate board is with lower cost. Here, please note it's not because the material's cost more higher, the effect is better. Anyway, you can decide according to your local situation and actual needs.

P.S.: 4.5mm calcium silicate board is suitable, 3mm is a little thin.

So you can choose the best surface board in your local place to save your raw material cost.

1.Foaming system (include boiler, eps foaming machine);

2.Raw materials storage / measuring / conveying system (include raw materials silo, storage& weighing &measuring hopper, pump, etc);

3.Mixing system (include mixing machine, electric control system);

4.Foaming and gating system (include vertical mould car)

VANJOIN GROUP is a high-tech building material company specialized in the R&D, production, and sales along with great after-sale service of new energy-saving light weight eps sandwich wall panel, wall panels production line, flexible tile and flexible tiles machine.

We now own a factory with more than 20,000 m2, and with a 32,960m2 new factory under established. We have patent of maknig the sandwich wall panels, and own research group in famous universities.

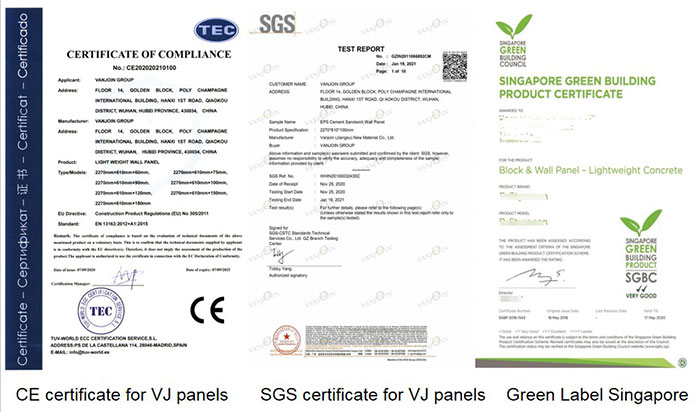

Our products have been certificated by CE, BV, SGS, ISO9001 & 14000, having been widely exported to UAE, Saudi Arabia, Qatar, Iran, Iraq, Russia, Cyprus, Ireland, Egypt, South Africa, Nigeria, Kenya, Uganda, Ghana, Australia, Maldives, India, Malaysia, Thailand, Brazil, Chile, Costa Rica, etc.

1. R&D Ability:

We have research and development team in famous Wuhan University, that's why we have such exclusive new products and panels.

2. Successful Experience:

We have supported many clients (both in domestic and abroad) set up their own plant with our machine/ production line, such as India, Thailand, Uganda, Kenya, Angola, Mexico, Saudi Arabia etc.

3. What you need to do?

Raw Materials: calcium silicate board, EPS, cement, sand, ceramisite, perlite or fly ash.

(if some material is not available at your local, we can also provide for you)

Land/ Factory Preparation

Workers

Installation Tools

4. What service and support you can get from VANJOIN?

Investment Cost Calculation

Factory Layout Design

Production Line Layout Design

Installation Guidance

On-site Training Service

Sharing of R&D Achievements

Got a question, comment or business enquiry? We are always happy to hear from you.